Gold Refinery “Tau-Ken Altyn” LLP

For processing of all gold to replenish the country’s gold and foreign exchange reserve, an enterprise for refining gold-containing raw materials with a nominal production capacity of 25 tons of refined gold and 50 tons of refined silver per year has been built, while the production and technological potential is sufficient to produce 70 tons of gold and 400 tons of silver per year.

The Tau-Ken Altyn gold refinery was put into operation in November 2013. It carries out activities for processing gold-containing raw materials (cathode and concentrate gold, jewelry and technical scrap, Dore alloy with a minimum gold content of 10%).

The final products within the framework of the pre-emptive right to acquire refined gold are sold to the National Bank of the Republic of Kazakhstan as a matter of priority to replenish the gold and foreign exchange reserve.

The refinery is located on the territory of the industrial park – Special Economic Zone “Astana – New City”.

The production and engineering staff of the refinery is manned with qualified personnel with extensive experience in the field of precious metals enrichment and refining, as well as practical training at enterprises in Italy and Russia. At the moment, 75 people are working at the plant.

The products of the plant are:

- refined gold with 99.99% quality, in the form of standard ingots, weighing 12 kg, dimensional ingots weighing 100 grams, 250 grams, 500 grams, 1,000 grams, granules;

- refined silver with 99.99% quality, in the form of standard ingots, weighing 30 kg, dimensional ingots weighing 100 grams, 250 grams, 500 grams, 1,000 grams, granules.

The technology of the refinery is developed in accordance with international innovative methods of refining precious metals, which are not inferior to world leaders.

When choosing the refining technology, one of the main selection criteria was the environmental friendliness of the processes used. In accordance with this, the technology of the electrochemical method of refining precious metals was chosen, which, in combination with the equipment used in the technological process, ensures absolute environmental safety.

Thus, in 2015, the technological line of the plant was supplemented with the latest innovative ACIDLESS SEPARATION unit, which provides the process of vacuum distillation of silver from gold-silver alloys. The technological process makes it possible to solve a number of important tasks and has an economic advantage achieved due to the high speed of processing of gold-silver alloy, high extraction of precious metals.

The introduction of hydrometallurgical gold deposition equipment was completed in 2017, which makes it possible to expand the range of raw materials for gold processing, and reduces the cost of a part of the products produced. This equipment made it possible to process additional types of raw materials, such as cathode gold, prepared electronic scrap, off-balance tailings.

The further development of the plant provides for the production of higher-grade products, in particular, the manufacture of blanks for the jewelry and technical industries, as well as the manufacture of dimensional ingots (from 1 to 100 grams) for sale to the public as investment gold. For these purposes, when designing the plant, areas were provided for further promising development.

On September 19, 2019, Tau-Ken Altyn LLP received a Good Delivery certificate. Also in 2019, the planned level of the design capacity of gold refining production in the amount of 25 tons was reached.

The following events are planned for 2022:

1) development of a strategy for the development of refining production of Tau-Ken Altyn LLP;

2) development of technology for processing solid industrial waste, taking into account the results of R&D;

3) development of technology for processing automotive catalysts and electronic scrap for the extraction of precious metals, taking into account the results of R&D;

Production of refined gold and silver by Tau-Ken Altyn LLP:

| Finished products | 2014-2020 actual | 2014 actual | 2015 actual | 2016 actual | 2017 actual | 2018 actual | 2019 actual | 2020 actual | 2021 actual | 2022 actual |

| Gold, ton | 131.8 | 6.3 | 10.1 | 12.0 | 18.0 | 22.7 | 29.2 | 33.5 | 51.1 | 55.6 |

| Silver, ton | 42.8 | – | 2.3 | 3.8 | 14.6 | 6.1 | 7.0 | 9.0 | 6.4 | 6.9 |

Silicon Plant of Tau-Ken Temir LLP

In compliance with the decision of the Council for Mining and Metallurgical Activities under the President of the Republic of Kazakhstan of December 05, 2013, JSC NMC Tau-Ken Samruk was appointed the operator for the implementation of the investment and strategic project “Preparatory Work and Launch of the Plant for Production of Metallurgical Silicon in Karaganda region” in order to revive and restart idle production. Tau-Ken Temir LLP was created to implement this project, which is a 100% subsidiary of JSC NMC Tau-Ken Samruk.

Description of the plant:

Design refinery capacity: 24 thousand tons of technical silicon per year.

The refinery is equipped with the equipment of SMS SIEMAG, the German company, two ore-thermal furnaces (OTF) with a capacity of 12 thousand tons of silicon each are installed.

The production of technical silicon in Kazakhstan is a new industry, the development of which began relatively recently. At the moment, Tau-Ken Temir LLP is the only manufacturer of technical silicon in Kazakhstan. The main raw material, quartz is supplied from the Aktas deposit of Karaganda region, owned by Silicon Mining LLP (a subsidiary of the Company).

In September 2014, ore-thermal furnace No.1 was put into operation after a long downtime.

In September 2015, the commissioning of ore-thermal furnace No.2 was carried out after the complete refutering of the furnace bath.

In 2016-2017, 2 stages of the Partnership’s investment program were implemented for the acquisition and modernization of production equipment and special machines.

In addition, since 2019, there has been decrease in prices for finished products on the market, therefore the Management Board of JSC NMC Tau-Ken Samruk decided to suspend the production activities of the silicon plant with the optimization of the staff number, taking into account the conservation of production, ensuring fire and industrial safety, and the safety of the property of the production complex.

At the moment, JSC NMC Tau-Ken Samruk carries out active work to attract investors to the project, and actively negotiates with financial institutions to provide funds for the launch of production.

Mining of vein quartz at the Aktas deposit in Karaganda region by Silicon Mining LLP

Silicon mining LLP was established on December 22, 2008 to extract and process vein quartz – the raw material for the silicon plant of Tau-Ken Temir LLP.

On December 09, 2016, JSC NMC Tau-Ken Samruk purchased 90.1% of the share in the authorized capital. On January 31, 2018, permission was obtained to buy out 9.9% of the share in the authorized capital of Silicon Mining LLP in favor of JSC NMC Tau-Ken Samruk.

Subsoil Use Contract No.2810 of October 09, 2008 Production period – 25 years (until 2033).

The Aktas quartz deposit is located in the Ulytau district of Karaganda region, 130 km northwest of Zhezkazgan ccity, 1.5-2.0 km from Aktas village.

To provide the mining enterprise with electricity, 110 and 35 kV power lines have been brought to the deposit.

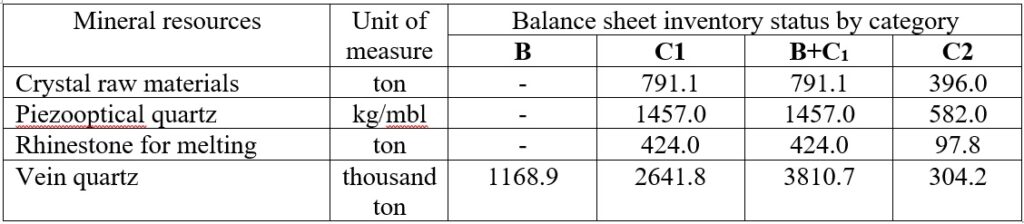

The reserves of the field are estimated in the following volumes, indicated in the following table as of January 01, 2019.

In addition, since 2019, there has been decrease in prices for silicon on the market, therefore the Management Board of JSC NMC Tau-Ken Samruk decided to suspend the production activities of Aktas field with the optimization of the staff number, taking into account the conservation of production, ensuring fire and industrial safety, and the safety of the property of the production complex.

At the moment, JSC NMC Tau-Ken Samruk carries out active work to attract investors to the project, and actively negotiates with financial institutions to provide funds for the launch of production.

LLP JV Alaigyr

Limited Liability Partnership “Joint Venture “Alaigyr” was established on October 20, 2011, to implement the project “Mining and Processing of Polymetallic Ores at Alaigyr Deposit in Karaganda Region”.

Alaigyr deposit is located in Karaganda region, on the border of Karkaraly and Shet regions, in 130 km south-east from Karaganda city. Aksu-Ayuly village, the administrative center of Shet region, is located in 60 km to the south-west.

Construction and commissioning of the mining and processing plant for the production and processing of polymetallic ores of Alaigyr deposit with the capacity of 900 thousand tons of ore per year is of great strategic significance for the development of industry and the social and economic progress of the region as a whole.

Тo implement this project, the following facilities were built and put into operation: Akchatau substation, 110 kV high-voltage line (143 km long), wells (3 pcs.), a road from the Kamkor settlement to the Alaigyr deposit, the frame of the processing plant, a railway dead end with the flotation concentrate warehouse, a production and administrative building.

Mining preparatory work was carried out in the amount of more than 5 million m3.

Currently, work is underway to update the key indicators of the Project. It is planned to carry out work on the construction of a processing plant, a tailing storage facility and infrastructure facilities, including a fuel and lubricants warehouse, a water conduit and sewage system, and a shift camp.

After putting the facility into operation, more than 500 jobs will be created at the facility. It is planned to attract mainly the local population with organization of training and subsequent employment at the enterprise.

Severniy Katpar LLP

The main activity of the Limited Liability Partnership is combined exploration and production of tungsten-molybdenum ores at the Severniy Katpar and Verkhneye Kairakty deposits.

- In relation to the Severniy Katpar deposit, following the geological exploration works, appraisal of mineral resources under the JORC Code and re-appraisal of reserves according to the State Committee on Reserves were completed, technological regulations for design of the mining and metallurgical complex were developed, the work on development of a preliminary feasibility study for investing the mine construction has been developed. And at the moment, the work on development a feasibility study for the construction of a mining and processing plant for the Severniy Katpar is in progress.

- In relation to the Verkhneye Kairakty deposit,following the geological exploration works, appraisal of mineral resources under the JORC Code was completed, the work on re-appraisal of reserves according to the State Committee on Reserves is in progress. Work is underway to develop a Feasibility Study report, including an assessment of the reserves of the Verkhneye Kairakty field according to the standards of the JORC Code (2012).

ShalkiyaZink LTD JSC

ShalkiyaZink LTD JSC is a mining company with exploration and production rights, owns the Subsoil Use Contract for the extraction of polymetallic ores at the Shalkiya deposit, as well as the Contract for the extraction of groundwater at the sections of wells No.1-8 of the Shalkiya deposit in Kyzylorda region of the Republic of Kazakhstan.

The total zinc reserves of the Shalkiya deposit, according to the BrookHunt Research Company (report as of November 2006), account for more than 30% of all reserves of the Republic of Kazakhstan and rank 5th among the largest deposit in the world with proven and probable reserves of 6.5 million tons of zinc according to the JORC classification.

The Shalkiya lead-zinc deposit was discovered in 1963. Exploration of the deposit began a year later, and over the next forty years was periodically renewed. Ore was mined at the deposit from the mid-1980s and up to 2008, but due to serious surges in world prices for metals throughout the entire existence of the mine, mining was not regular, and work was repeatedly stopped.

At one time, great hopes were pinned on the expansion of the deposit: it was planned to build three mines, which, unfortunately, were never equipped.

In 2008, the development of the project was prevented by the global financial crisis and construction was postponed.

Nevertheless, plans were made to expand production and build a processing plant at the Shalkiya field. To this end, studies were carried out in 2016 to confirm the reserves at the field:

Micon International performed Mineral Resource Assessment for the Shalkiya lead-zinc deposit for ShalkiyaZink LTD JSC, in accordance with the JORC Code (2012). Also, supporting technical report “Estimation of Reserves of the Shalkiya Lead-Zinc Deposit” was prepared.

ShalkiyaZink LTD JSC hired the German company Engineering Dobersek to develop the technological regulations for a concentrating mill with the capacity of 4 million tons per year for processing of lead-zinc ore from the Shalkiya deposit. The regulation was developed on the basis of the latest research carried out by Engineering Dobersek, taking into account numerous studies performed by various organizations of Russia, near and far abroad, as well as the practice of industrial processing of ore at the Australian processing plant “MMG Century”.

At the beginning of 2020, under the leadership of the National Mining Company “Tau-Ken Samruk”, a project group was created consisting of highly professional civil engineers, geologists, mine builders, technologists, IT and other narrow specialists.

A new Strategy for the implementation of the project was adopted, in particular, the progress of the design and construction was analyzed, problematic issues affecting the quality and timing of the project were identified. Thanks to the serious preparatory work of the project team, in May 2020, the design of the concentrating mill at the Shalkiya field began, as well as the adjustment of documentation for the mining part of the Shalkiya project.

The commercial products of the concentrating mill at the Shalkiya deposit are:

– lead flotation concentrate corresponding to the KC-7 grade;

– zinc flotation concentrate corresponding to the KЦ-4 grade;

The concentrating mill for processing polymetallic ore is planning to use modern, high-tech equipment with a high degree of automation for the stable operation of the technological process, achieving the required production indicators and minimizing the impact on the environment.

The enrichment process includes the following stages:

– coarse, medium, fine crushing in jaw and cone crushers and fine crushing in abrasive high pressure grinding rollers (HPGR);

– grinding;

– selective flotation of lead and zinc;

– fine regrind of the concentrate of the main zinc flotation

– dehydration.

Crushing and grinding processes are used to achieve the required particle size before minerals are exposed, a factor that is critical for the subsequent flotation process.

Flotation process based on the difference in the physical and chemical properties of the surface of minerals. To separate valuable minerals from gangue minerals, flotation beneficiation uses chemicals called flotation reagents to regulate the physical and chemical reactions of the process. The range of used flotation reagents is traditional for direct selective flotation of lead-zinc ores.

The design scheme for ore processing obtains three enrichment products:

– lead concentrate;

– zinc concentrate;

– flotation tailings.

Both concentrates go through the dehydration stage. Lead and zinc concentrates, after thickening and filtering to optimum moisture content, are packed in big bags or in bulk in wagons for subsequent transportation to the consumer. The flotation tailings are sent without dehydration to the tailings dump for further storage.

Today, as part of the design of a mining and processing plant with production capacity of 4 million tons of ore per year, the process of the project digitalization is considered, which implies a high level of automation (the level of the automated process control system), the construction of BIM models (CAD-level), the MES-level is worked out with the transition to ERP systems. Innovation and digitalization of processes play an important role in the development of the industrial sector in Kazakhstan and affect the improvement of production quality and risk reduction.